Overview

Imagine a car as a complex ballet of interconnected parts, each playing a vital role in its movement. Multi-body dynamics (MBD) is like having a backstage pass to this intricate dance, using advanced mathematics to understand how forces and motions affect every component, from the powerful engine to the tiniest suspension bushing. Think of it as a sophisticated puppet show, where instead of strings, complex equations govern how these parts interact. MBD helps engineers build virtual models of the car, dissecting its behavior under various conditions. They can analyze how the suspension absorbs bumps, how the wheels turn during cornering, and even how the chassis flexes under stress. This virtual testing ground has revolutionized car design. Engineers can optimize suspension systems for a smoother ride, predict handling characteristics for safer driving, and even assess crashworthiness to keep occupants protected. It's like having a crystal ball for car performance, allowing them to fine-tune every aspect before ever laying a wrench on a real vehicle. MBD isn't just about flashy tech; it's about creating safer, more efficient, and enjoyable cars for everyone. It's like having a superhero sidekick for car engineers, helping them craft the vehicles of tomorrow, one simulated test drive at a time.

What Clients get

Why is MBD necessary ?

Forget paper trails and misinterpretations, MBD revolutionizes communication between design and manufacturing. With a single, rich 3D model, design intent flows seamlessly into inspection programs, eliminating human error in interpreting 2D drawings. No more "paperless inspection" dreams - it's reality. But the magic doesn't stop there. MBD automates part program creation, automatically adapting to design changes and keeping dependencies in sync. Imagine 80 hole tolerances updating with a single click - that's the power of MBD, saving time and boosting efficiency for complex parts and beyond. MBD isn't just a fancy term, it's a game-changer in how we manufacture.

What we cover

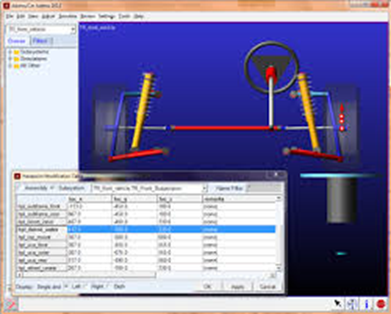

Suspension: To keep a car’s handling smooth, the suspension system relies on the concerted effort of various dampers and stabilizers. Multibody dynamics simulation can model all the interrelated parts of a suspension system to optimize performance.

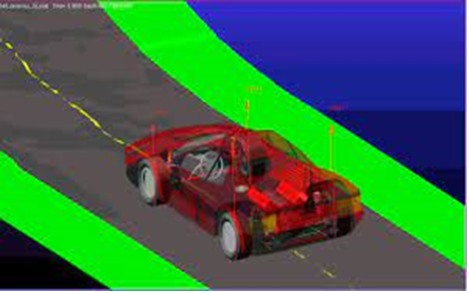

Powertrain: Multibody dynamics simulation can be used to improve the design and behavior of powertrain components, such as the engine, transmission, and drivetrain, for better performance, efficiency, and durability. Safety: To evaluate the stability of a vehicle, multibody dynamics simulation can model vehicle kinematics in rollover tests.

NVH: Controlling the noise, vibration, and harshness (NVH) levels within a vehicle is critical to passenger comfort and overall experience. By using multibody dynamics simulation, automotive engineers can identify the sources of vibration and sound emitting from all parts of a car and determine the best ways to address them.

Imagine intricate machines like a conductorless orchestra, each part playing its role, but will the song be beautiful? Enter multibody dynamics simulation, the maestro of machines. It builds virtual models, letting engineers see how every gear, spring, and wire dances together. By tweaking components and playing out scenarios, they harmonize the movement, ensuring each piece works in perfect rhythm to power our world, from towering wind turbines to your tiny phone, all conducted to perfection.